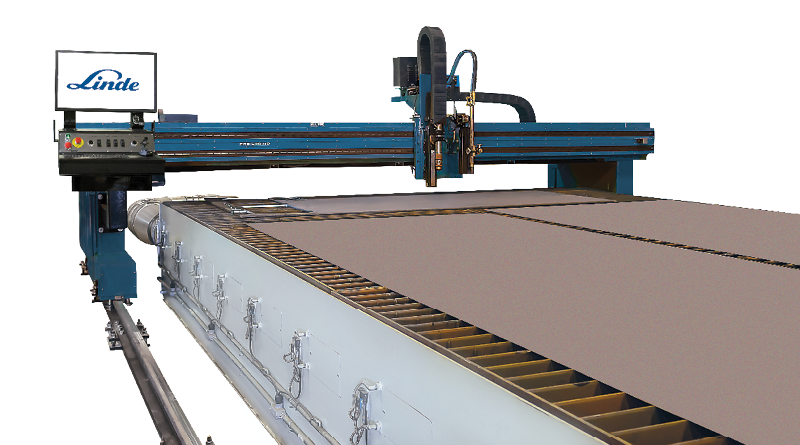

ProStar™ Plasma Cutting Table - PRS500HD

The ProStar™ PRS500HD CNC plate cutting system is designed and built for large fabricators and steel service centers where precision and reliability within a 24/7 production schedule is critical. This easy-to-use machine features heavy-duty construction and floor-mounted rails to facilitate multiple torches cutting on large and/or thick material. Advanced motion control enables use of conventional plasma or high-amperage, high-definition cutting systems for superior cut quality. CNC control in the PRS500HD CNC plate cutting system supports all of the functions required for oxy-fuel, contour-bevel plasma cutting, and/or drilling, as well as file conversion and part tracking.

Standard Equipment

- Dual side-drive gantry with high-powered Bosch Rexroth® AC bruchless drives

- Floor-mounted 30 lbs./ft. machined rails, adjustable leveling pads, dual drive, and digital synchronization

- Hypertherm® EDGE Connect® numerical controller with USB interface and wireless networking

- 19 in. active matrix LCD touch screen

- Power track guide and heat shields to protect hoses and cables from wear and sparks

- Water table control at the operator's console

- Non-contact electronic proximity switches

- Rack and pinion drive with precision planetary gearbox

- 18 homing positions and procedures to square the gantry during setup

- Air blast and wiper system to clean rails

- 2 in. stainless steel drive band for slave/mirror image cutting

- Three-part automotive paint finish

Available Options

- 5 hp drill station integrated with PLC

- Options for tapping, countersinking, and counter-boring

- 12-station toll changer

- 5-axis Rotobevel contour beveling station

- X & Y axis plasma arc bevel station

- Adjustable oxy-fuel torches to allow beveling

- Laser pointer for plate alignment

- Hose reel with hand torch for hand cutting

- Torch collision sensor with plasma systems

- Precision micrometer-scaled oxygen piercing valve for oxy-fuel systems

- Plasma, pneumatic or paint marking

- Heavy-duty or easy-to-clean water/downdraft tables

- Floor-mounted or over-head power track

- Rider console with cushioned seat

- Tucked rail for forklift access

- Precision-machined linear profile rails

- Automated gas control console

Standard Configuration

| Part No. | Cutting Width | Cutting Length | Lifter Speed: Plasma | Lifter Speed: Oxy-Fuel | Machine Speed: Traversing | Machine Speed: Contouring | Cutting Capacity: Plasma | Cutting Capacity: Oxy-Fuel | Maximum Stations: Plasma | Maximum Stations: Oxy-Fuel | Maximum Stations: Drill |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PRS500HD | 10 ft. | 10 ft. | 1,000 ipm | 70 ipm | 1 ipm - 1,000 ipm | 1 ipm - 500 ipm | Up to 2 in. mild steel Up to 2 in. aluminum and stainless steel | Up to 10 in. | 4 | 24 | 1 ea. 15 hp / 1.5 dia. hole |

Specifications subject to change without notice.