Flux Cored Welding

Flux-Cored Arc Welding (FCAW) utilizes a continuously-fed tubular electrode, electrical power to melt the electrode, and may or may not use shielding gas from an externally supplied source when depositing material in the weld joint. The flux-cored electrode is a composite tubular filler metal consisting of a metal sheath with a core of mineral compounds and powdered metals. The resulting weld bead is covered by a residual slag (melted and solidified flux) which helps to protect and shape the finished weld, and is generally easily removed upon completion of the weld. Flux Cored Welding combines the high productivity of MIG welding using a solid electrode with the ability to weld on more contaminated base material. When compared with MIG welding, higher deposition rates are possible, especially when welding out of position.

There are three types of flux-cored wires available:

- Gas-shielded all position

- Gas shielded flat position

- Self-shielded

Each has its own advantages.

The type of Flux Cored Welding wire used depends on the welding position, the mechanical properties required, the type of joint and its fit-up, and the environment in which the welding is to be performed. Generally, self-shielded wires are used for welding outside or for special applications such as welding galvanized steel. Among the most common are outdoor construction and fabrication in areas where gas cylinders and gas shielding cannot be readily used. Gas-shielded flux-cored wires are used in operations such as shop fabrication, maintenance, and shipbuilding. Flux-cored wire welding is especially useful where the base material to be welded has some amount of scale, rust or other surface contaminants present. With the proper selection of wire type and shielding gas, weld properties are excellent for many types of materials.

All-position wires (E-71T-1) are typically smaller than 1/16” in diameter and are formulated with a fast-freeze flux. They are not well suited for use where high levels of base metal contamination exist, but offer good control when welding in the vertical up or over-head position. Shielding gas selection can be pure CO2 or C25. In all instances, the shielding gas selected should be matched with the recommendation of the filler metal manufacturer. Failure to do so may result in poor quality welds. A common problem from incorrect gas selection is weld cracking.

Flat-position wires (E-70) can be utilized in the flat or horizontal welding positions. They are typically greater than 1/16” diameter and are primarily applied for high deposition welding on thicker base materials (>1/4”) This family of wires offers a greater resistance to base metal contamination, and they have been shown to perform well over some rust and mill scale. Good welding practice dictates that the base metal should be cleaned of contamination prior to welding but, if this is not possible, these wires are the preferred choice.

Additional Questions

Why use Flux Cored Welding?

- High-quality weld deposit with excellent appearance

- Can be used to join many types of metals over a wide thickness range

- Relatively high electrode efficiency and process duty cycle

- Excellent weld penetration simplifies joint design

- The arc is visible and easy to use

- Because of its greater tolerance for base plate contamination, Flux Cored Welding requires less pre-cleaning than MIG

- Deposition rate is up to four times greater than Stick Welding

- The use of self-shielded electrodes eliminates the need for flux handling or gas apparatus, and is more tolerant of windy conditions present in outdoor construction than gas-shielded processes

What are some limitations of Flux Cored Welding?

- Presently limited to welding ferrous metals and nickel-based alloys

- Process produces a slag covering that must be removed

- Flux Cored Welding electrode wire is more expensive on a weight basis than solid electrode wires, except for some high alloy steels

- Equipment is more expensive and complex than required for Stick Welding; however, increased productivity usually compensates for this

- In general, more fume is generated than with MIG welding

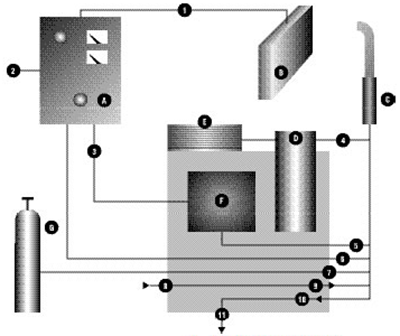

| A Power Supply | 1 Power Cable (negative) |

| B Workpiece | 2 To Primary Power 230/460/575 V |

| C Welding Torch | 3 115 VAC In - Welding Contactor Control |

| D Wire Feed Motor | 4 Wire Conduit |

| E Wire Reel | 5 Torch Switch |

| F Welding Control | 6 Power Cable (positive) |

| G Shielding Gas | 7 Shielding Gas from Cylinder or Bulk Supply |

| 8 Cooling Water In | |

| 9 Cooling Water to Torch (optional) | |

| 10 Cooling Water from Torch (optional) | |

| 11 Cooling Water Out (optional) |