ProStar® Welding Wire

Metal fabricators choose premium quality ProStar welding wire for its superior strength, consistency, and twist-free performance.

For over 14 years, ProStar wire has been produced at a single ISO-certified mill specifically chosen for its ability to consistently draw extremely clean green rod. Critical manufacturing equipment is routinely replaced to insure the highest possible quality. Tight control over the selection of the rod, the drawing process and the alloying elements insures ProStar welding wire will have the most consistent columnar strength available in the industry today.

- ProStar wire can be fed over long distance to your weld cell and maintain excellent arc starts and feedability characteristics

- Larger parameter optimization window

- Most consistent columnar strength in the industry today!

Welding wire without our twist-free characteristic will result in major intermittent feeding issues during your manufacturing process.

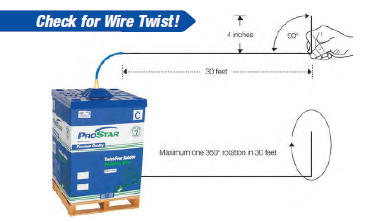

Make a small wire loop. Ask someone to hold the loop while you pass wire from PAC through the loop. Make a 90 degree bend in the last 4-5 inches of the wire. Hold the wire end as you pull 25-30 feet of wire from the PAC. The wire should naturally rotate clock wise no more than one full rotation over 30 feet.

If your welding wire fails this simple test, contact your Linde representative or call 1-800-225-8247 to learn more about the ProStar welding wire system.

Linde’s 24/7 Continuous Wire Feed System for Robotic Welders

The ProStar welding wire system features our exclusive wire packaging: including an automatic switchover device and our maintenance-free conduit that provides twist free, low drag 24/7 wire delivery to your welder.

- Increase productivity and eliminate downtime

- Improve profitability and maximize savings with reduced waste

- Save floor space-wire PAC can be located up to 150 feet from the robotic cell

The ProStar welding wire system provides a continuous supply of welding wire to your robot.

How it Works

A butt-welding machine joins the wire end of the primary PAC to the wire-start of the next full PAC. When the primary PAC is empty, the boom automatically switches from the primary PAC to the reserve PAC without any operator intervention.

After replacing the original PAC with a full PAC, the operation is repeated in the opposite direction, again and again, providing a continuous, uninterrupted supply of Prostar welding wire.

Newly redesigned ProStar wire packaging reduces moisture vulnerability and provides even better feedability.

Packaged for Productivity

- Double plates and corner supports improve feedability and eliminate tangling due to material handling

- Plastic-sealed carton is packed with dessicant powder to prevent rusting

- All hoods supplied free of charge

- 50% of the package is 100% recyclable plastic, 25% recyclable cardboard, 25% wood

- Easy package dismantling

ProStar Wiring System Features and Options

- Forklift-friendly, palleted PACs

- Double-stacking design and standard “foot print” forall PAC sizes helps reduce required storage space

- Unique corner supports inside the PAC prevent box deformation

- Wire sealed inside a plastic bag with desiccant packs to help prevent rust

- Excellent feedability

- Smaller spools available

- Minimizes burn-backs and bird-nesting

- Proprietary wire-winding process minimizes arc wander

- Wire quantity view port on all PACs

- Available wire quantity monitor stops the robot welder when the wire runs out and sounds an alarm