Resistance Welding Automation

RAMP UP your APPLICATION!

Linde can help you lower costs and boost productivity.

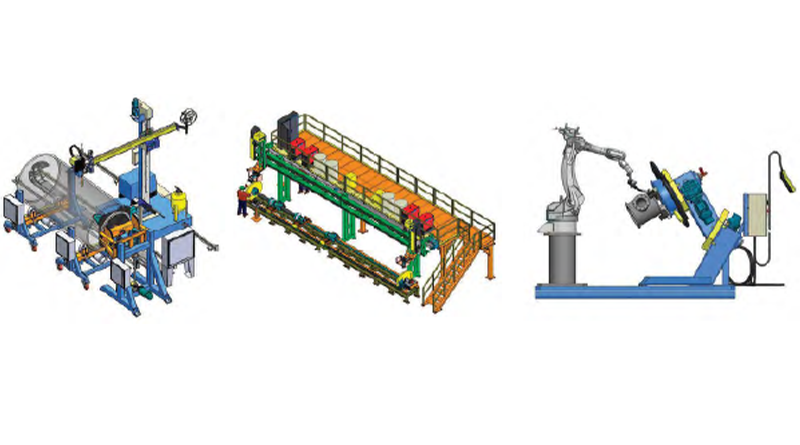

Linde custom-engineered system fit your budget and project needs. We have the flexibility to design and build any size system ranging from small to medium-size pedestal units to large, integrated robotic packages. Linde productivity experts can help you decide which solutions bring the best balance of cost and functionality to meet your specific resistance welding needs.

Linde will customize your robot to better address your welding needs.

- We can customize a pre-engineered robotic weld cell specifically for your welding application.

- Linde robot programming and weld development optimizes cell performance, minimizes inefficient air moves, and maximizes weld travel speeds and thoughput.

Other Productivity Options

- Programmable logic controllers (PLC) and Human Machine Interfaces (HMI) drive more complex fixtures and provide on-screen system diagnostic and production monitoring, Linde can also enable networking between your machines and your company's IT system.

- Tourch maintenance system (nozzle "reamers") increase up-time and weld quality.

- Fume hoods built for your specific weld cell improve air quality and operator working conditions.

- Part-marking systems can add tracking information such as date/shift, fixture number, serial number, etc.

Small Welding Systems

Linde addresses smaller resistance welding applications with operations that can be performed on simple “pedestal” welders, which lowers your capital investment and increases production.

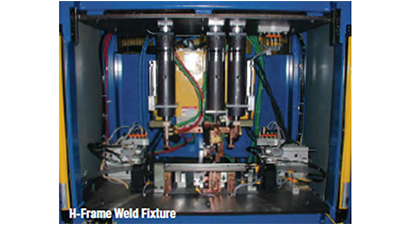

Medium Welding Systems

Multi-gun weld stations, sometimes called H-frames, can be used when multiple welds are to be made in a single sequence.