What is HeliStar A-25, A-50, and A-75?

Argon, Helium, and Argon/Helium Gases and Blends

Argon is the most commonly used gas for MIG welding aluminum and other nonferrous materials. Argon provides good arc starting and stable metal transfer due to its low ionization potential.

Helium, due to its high thermal conductivity and high ionization potential, produces a hotter, broader arc which improves the depth of penetration and weld bead wetting characterisitcs. Helium-enhanced argon blends are generally preferred over pure argon for joining heavy sections of base metal which have high thermal conductivity. Helium can be used to reduce the level of ozone generation when welding aluminum.

Blends of argon and helium are frequently selected for MIG welding to promote higher travel speeds. Linde's HeliStar™ A-75 blend is used where some additional heat input is required while maintaining the favorable arc-starting characteristics of pure argon. It is the most widely used blend for MIG welding thick aluminum sections. It is an excellent choice for the pulsed spray welding of aluminum and for use when 5000 series filler wires are necessary.

Linde's HeliStar A-50 blend is used primarily for high-speed mechanized welding of non-ferrous materials under 3/4" thick.

Linde's HeliStar A-25 blend enhances the speed and quality of mechanized welds in aluminum.

| Product Features | Benefits |

|---|---|

| Argon base |

|

| Helium enhancement |

|

| Optimized blend of Ar/He |

|

Typical Applications

- Aluminum boats

- Automotive panels/frames; hoods/body panels

- Aluminum ladders

- Aluminum tool boxes for pick-up trucks

- Transformers

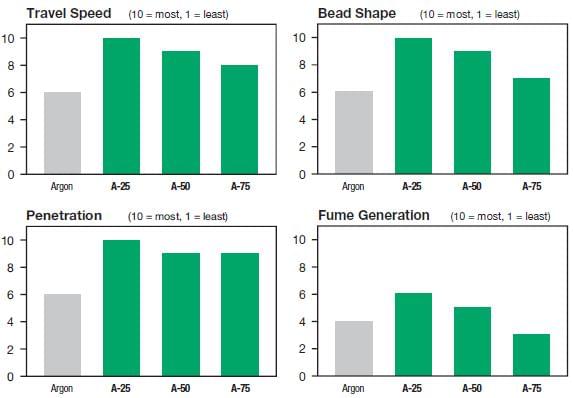

Below are comparisons between shielding gas blends over a range of operating conditions. They are intended to provide suggestions for gas blend selection based on the criteria indicated.

Note: The selection of the appropriate shielding gas can be complex due to the variety of operating variables (base metal chemistry and thickness, transfer type, wire selection and welding position). Consult your Linde representative to help you choose the best gas for your application.

Welding Conditions Selection Table

| Wire Diameter (in) | Wire Feed Speed (ipm) | Current Level (amps) | Volage (volts)* |

|---|---|---|---|

| 3/64 - 4043 | 225-375 | 140-170 | 23-25 |

| 3/64 - 5356 | 300-425 | 160-190 | 24-26 |

| 1/16 - 4043 | 225-275 | 175-230 | 25-26 |

| 1/16 - 5356 | 300-375 | 210-250 | 26-27 |

* Voltage level for 60 Hz power supply. With 50 Hz, add 3 volts. For Ar/He, add 2 volts.