7 CNC Machining Tips and Techniques to Increase Productivity

CNC cutting machines are widely used in a variety of industries for precision cutting and drilling and are among the most vital—and costly—pieces of equipment on the plant floor. For most companies, they represent significant capital investments and therefore must maintain their performance for many years. Here are some tips for optimizing productivity with your CNC cutting machine.

1. Use High-Quality CNC Machine Cutting Tools

Using the right cutting tools for your material is crucial for getting the most out of your CNC cutting machine. Save yourself a headache and some money by avoiding cheap cutters that quickly wear out and easily break. High-quality machine tooling is made to withstand the forces of high-speed machining, providing better quality and consistency in your production.

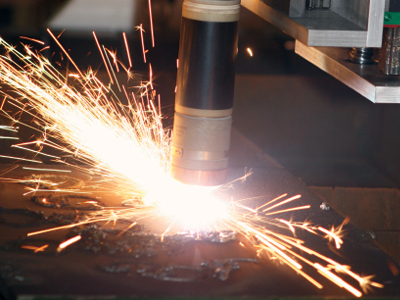

2. Use the Right Cutting Speed

The speed at which you cut will depend on the material you are cutting. For example, cutting metal at a high speed can cause heat buildup, which can lead to warping or melting. On the other hand, cutting wood at a slow speed can result in rough edges or burning. Experiment with different speeds to find the optimal setting for your specific process and cutting machine tool.

3. Properly Choose and Maintain Machine Software

There are many software options available, but not all of them are created identically. A good CNC machining CAD/CAM software package can help you ensure that your parts are produced to the proper dimensions and can easily be manufactured in a precise and repeatable way. Additionally, keeping the machine software up to date over time is critical for ensuring smooth operation, fixing bugs and getting the most out of your machine.

4. Properly and Regularly Calibrate Your Machine

Regularly calibrating the machine is essential for ensuring that the cuts are accurate. A well-calibrated machine will make precise cuts, reducing the need for rework and minimizing waste.

5. Use the Right Cutting Fluid

Cutting fluids are often used to cool and lubricate the cutting tool, and to flush away chips and debris. The type of cutting fluid you use will depend on the material you are cutting. For example, water-based cutting fluids are commonly used for cutting metal, while oil-based cutting fluids are used for cutting wood.

6. Check for Wear and Tear

Regularly inspecting the machine's moving parts, such as the cutting head, for wear and tear is essential to ensuring that the machine is operating at its best. Replacing worn parts as soon as they are detected will help to avoid costly downtime in the future.

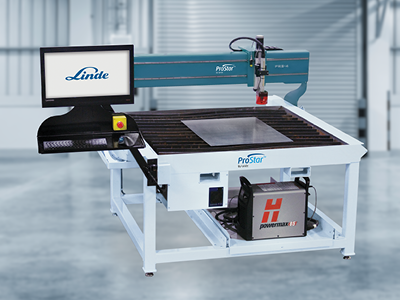

Linde can help breathe new life into your older CNC cutting machines with a complete overhaul performed at your facility. We can retrofit and replace controls, drives, gearboxes, motors and plasma or oxy-fuel systems so that your rebuilt machine can perform at peak performance.

7. Keep Your Machine Clean

Regularly cleaning your CNC cutting machine is essential for maintaining its accuracy and prolonging its lifespan. Make sure to remove debris and chips from the cutting area after each job and clean the machine's internal components as needed.

Take Your Production to Higher Speeds

By following these tips, you can ensure that your CNC cutting machine is running at its best, resulting in more accurate cuts, longer tool life and increased productivity. Remember that the key to optimal performance is regular maintenance and care, so be sure to establish a regular schedule for checking and maintaining your machine. For more information about CNC machine maintenance and to learn more about Linde’s offering of CNC cutting tables, tools and software, contact us at 1-800-225-8247.