Productivity Matters

A Cleaner, More Consistent Wire

As metal fabricators make large scale improvements, they often rely on Linde’s StarSolver® Productivity Enhancement Program to help identify the adjustments that will make the most sense – both for their productivity and profitability goals. One of the most common improvements is adding a robotic welding cell. Robotic welding delivers high throughput, improved weld quality and consistency at a financial advantage when compared to the cost of locating and adding experienced and talented welders to a line.

“For a number of factors, robotic welding is fast becoming more affordable and flexible to fabrication shops large and small,” said Robert Schaefer, National Marketing Manager for Linde. “For our larger customers that participate in the StarSolver program, we often identify robotic welding as an effective way to streamline operations and improve production times.” But using standard welding wire and consumables can limit the ability of your robotic welding cells to consistently and efficiently produce quality welds.

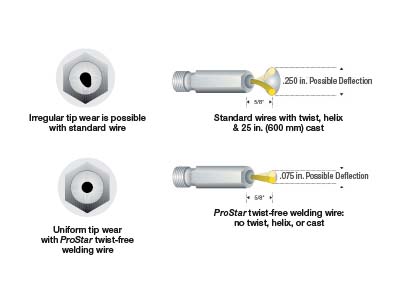

Linde’s ProStar™ twist-free welding wire helps metal fabricators maximize the benefits of robotic welding cells. Standard welding wire packs for automated processes often suffer from issues associated with excessive cast and helix, causing uneven wear on consumables, a wandering arc and over-welding, as well as added post-weld cleanup and rework costs. This can also be compounded by wire feed issues, which ultimately force you to shut down your line, costing you time and money – costs that far exceed any perceived savings when purchasing a standard wire product.

ProStar welding wire is twist-free and provides excellent wire feedability. ProStar twist-free welding wire is the right choice for meeting the high demands and expectations placed upon automated welding processes for consistently high throughput and quality.

Unmatched quality

Linde only sources wire from one mill, specifically selected for its ability to consistently draw clean green rod within exceptionally tight tolerances. From drawing and packaging to delivery and use, Linde delivers a high-quality, predictive welding wire with a maximum wave amplitude of 6 inches over 10 feet with virtually no cast or helix. Add its exceptionally consistent chemistry, wire diameter, wire surface cleanliness and smoothness, ProStar twist-free welding wire stands above all other standard welding wires.

In fact, ProStar welding wire bulk PACs were designed with your needs in mind.

- Stackable to take up less floor space

- Forklift accessible on four sides for ease of transport and placement

- Inner packaging to reduce the effects of moisture

- Corner supports to prevent tangling due to material handling

“Linde’s ProStar welding wire is by no means ‘new’ to the market,” said Robert Schaefer. “But in the spirit of ProStar and Linde’s commitment to sourcing and providing premium products to our customers, there is no better product to showcase that fact than our welding wire.”

Benefits on a fast track

Following a successful StarSolver audit and installation of ProStar twist-free welding wire and wire feed conduit system, customers very quickly can observe production improvements and profitability improvements over time. A cleaner, more consistent wire helps eliminate wire feed issues, reduce downtime and protect your productivity so that your machine spends more time doing exactly what you installed it to do – to deliver high-quality products efficiently.

ProStar twist-free welding wire can also help to extend the life of welding consumables, which extends predictive weld puddle placement, reduces overwelding and reduces cost per inch of weld.

Linde also went beyond the welding wire and implemented an exclusive welding wire conduit called EasyGlide™. EasyGlide is a continuous wire feed system for robotic welders that significantly reduces wire friction, allowing it to be used over greater distances than conventional conduits. This allows you to place your wire PAC where it is convenient for your operation, possibly freeing up operational space around your robotic welding area.

“Unlike standard welding wire, ProStar welding wire helps assure a more even and uniform tip wear,” said Schaefer. “ProStar premium welding wire helps reduce your consumables usage and overwelding while improving weld quality resulting in savings that really add up.”