Productivity Matters

Choosing Laser Assist Gases

Oxygen-, Nitrogen- or Air-Assist for Laser? Consider the Application Before You Make the Cut

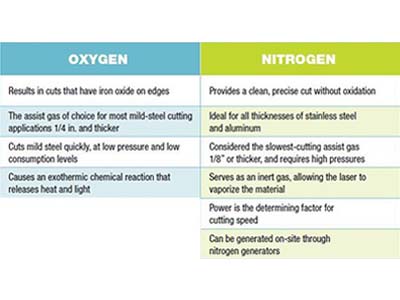

But beyond these basics, shop managers must weigh a number of critical factors in order to choose the right assist gas for the job. Indirect labor costs, desired edge quality, gas expense, and laser power all need to be considered before making the cut. According to Mark Mercurio, Applications Manager for Mazak Optonics Corp., choosing wisely means considering the application from gas supply to laser resonator to finished piece. “Think about how the part is going to be used, and then choose the assist gas based on that.” Praxair’s Chris Vihnanek agreed. “You really have three gases to consider — oxygen for cutting steel in applications where the edge will be oxidized, nitrogen for clean cuts where you need to eliminate some indirect labor costs, and air.

What About Air?

At one time, compressed air was thought to be virtually free. But with the cost of electricity across the U.S. ranging from $0.06 to $0.20 per kW — plus expenses associated with producing a clean, contaminant-free air supply — “free” can be a more costly proposition than you think. Nitrogen and oxygen aren’t always the best answer for laser cutting. For instance, if the material is galvanized or aluminized steel, shop air will cut twice as fast. Air can also be used to cut aluminum and some thinner steel. That said, in every case the air used to cut metal must have a minimum purity. Compressed air contains water and oil that can quickly foul a focusing lens. This contamination restricts the amount of energy that can pass through the optic and may significantly impact the life of the lens.

In most shop environments, a minimum treatment that addresses oil and water contaminants might involve installation of a refrigeration air dryer to reduce water content to less than 2,000ppm of water. The addition of a D13G dryer can further reduce the water content to less than 100ppm, or a -40°F pressure dew point (PDP), while eliminating the contaminant dust a desiccant dryer leaves behind. Oil should be managed by asking your air compressor serviceman to set a low oil concentration, maintaining total hydrocarbon (THC) levels at less than 2ppm and zero droplets. Using air may not make for the cleanest cuts, and it’s often harder on lenses. But the extra speed that can be achieved keeps air on the shortlist of viable assist gases — especially in applications that provide enough extra profit to cover the cost of new lenses.