Productivity Matters

Enhancing Your Welding Productivity and Profitability with Praxair’s StarSolver™ Program

In today’s global economy, metal fabricators pursue operational efficiencies that allow them to stay competitive, while simultaneously making smart investments. This is more than just a desire to control costs; it’s an effort to make strategic decisions that lead to sustainable practices that maximize machine uptime, which translates into larger profit margins. To meet these challenges, fabricators must reduce production costs, increase product quality and comply with increasing environmental regulations.

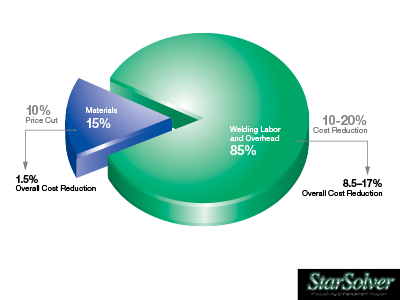

To assist you in controlling and reducing manufacturing costs, we developed Praxair’s StarSolver™ Productivity Enhancement Program. As part of the program, Praxair’s productivity specialists utilize software-based productivity surveys and engineering studies to accurately and systematically analyze your overall production costs and recommend process changes to improve performance where appropriate. This is especially important for assessing the impact of labor and overhead, which account for 85% of overall welding costs.

How It Works

The StarSolver Program process begins with Praxair’s MetFab Productivity Specialists (MPS) reviewing your shop’s current welding or cutting operations from start to finish – all with as little disruption to your work as possible. By gathering comprehensive data about your production processes, labor and overhead costs, the team can do a complete analysis of your plant’s productivity and find ways to improve it.

Your StarSolver evaluation may include:

- Gas analysis

- Gas-to-wire ratio

- Weld size

- Automation potential

- Welding processes and equipment

- Operator duty cycle measurements

- Electric power consumption

- Cutting analysis (laser, plasma, oxy-fuel)

… and much more.

Based on our findings, Praxair will recommend a realistic list of actionable items, which may include process, material, equipment or facility changes or improvements. Working together, your customized action plan will be finalized and specifically designed to make increased throughput and greater profitability attainable while keeping your budget in mind.

We’ll also follow up to make sure the new products and equipment are implemented properly and continuing to deliver the expected benefits.

A Cost-Effective Program

As previously mentioned, using Praxair’s StarSolver Productivity Enhancement Program, we collect current operating data and analyze it to determine if – and where – improvements can be made. Through the work of our MPS team, Praxair has helped customers dramatically reduce costs and increase productivity by as much as 20 – 40%, often with little or no capital investment. So instead of requiring a broad range of costly and nonessential changes, the Praxair StarSolver program targets areas that are critical to your operation, while working to improve performance.