Maximize Productivity and Consistency for Tube and Pipe Welding with Orbitec™ Welding Equipment

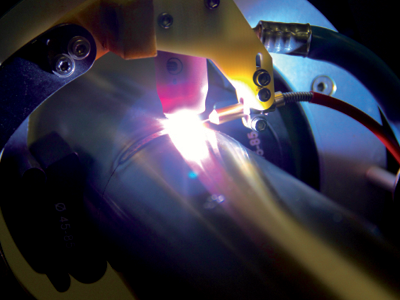

In a previous blog, we discussed orbital welding – what it is and when you should use it. First used in the 1960s when the aerospace industry recognized the need for a better joining technique for aerospace hydraulic lines, orbital tube welding serves a wide range of high-technology industries that require tubing systems. Semiautomatic orbital TIG welding allows for a quality weld of rounded parts by rotating the welding head around stationary pipe or tubing. And because of this, it is frequently used to weld difficult-to-reach joints in limited spaces.

Orbital TIG welding maximizes increased productivity by allowing an operator to maintain precise control of amperage and heat input, travels speed and filler metal use, in order to achieve consistent, reliable welds of high strength, continuity and cleanliness, with minimal deformation or contamination.

Linde provides high-quality orbital welding equipment that is focused on the practical needs of our customers. The Orbitec™ line of equipment is safe and easy to use with a modular design, where possible, to maximize productivity and help reduce costs. Linde’s Orbitec orbital tube welding is not only economical, but offers unique features such as data acquisition, oxygen analyzation and pressure control interlock.

Below is a list of the Orbitec welding equipment offered by Linde.

Linde’s Orbitec Welding Equipment

- Orbital TIG Welding System

High quality and reasonably priced, the Orbitec orbital TIG Welding system may be used for sanitary tubing, process piping, tube to tube sheet exchangers and circumferential welds on precision parts.

- Orbitec Tigtronic Welding Power Source

The Orbitec Tigtronic Welding Power Source offers strong arc characteristics that allow for welding between 1 and 150 amps when powered by 115VAC input power and is capable of 200 amps output when powered by 230VAC single phase input power.

- Orbitec Tigtronic Control

With interlocking capability, the Orbitec Tigtronic Control’s oxygen analyzer and purge pressure monitor helps ensure the required result each time you weld. Coupled with password level operation, the Tigtronic provides weld quality reports in both paper and electronic format that include date and time stamp, as well as operator sign-in detail.

- Orbitec OSK Line of Closed Weld Heads

Modular in design, the Orbitec OSK line of closed weld heads includes motors with direct gearing and encoder monitoring of position to provide high travel speeds and location control. The closed heads can be removed from the drive handle to allow more flexibility in your operation.

- Cable/Drive-Handle Assemblies

Linde not only provides Orbitec power supply/control combinations but also a number of attractive orbital welding power source/control combinations.

- Welding Collets

Installed in seconds rather than minutes, Orbitec welding collets are a result of the simple design of this weld head.

- Oxy3, Oxy2 and Oxy Smart Oxygen Analyzers

These models offer high performance in oxygen detection in Argon and Argon/H2 mixed gases. Hand-held or machine-interlocking equipment is available.

- Orbitec OSK13S Micro-fit Weld Head

The Orbitec OSK13S micro-fit weld head can be operated on both competitive orbital power sources as well as the Tigtronic Compact from Orbitec. The micro-fit cassettes are interchangeable with other well-known cassette heads.

Linde Knows Welding

Distributed by Linde, welding equipment from Orbitech can save you time and money while producing high quality welds on tubing and pipe. To complete our highly comprehensive offering of orbital welding equipment, Linde also offers special fixture tools, weld joint prep saws and facing tools, open arc orbital weld heads with wire feed capability, tube to tube sheet weld head and positioners with torch AVC control. Contact your local Linde representative or contact us at 1-800-225-8247 to learn more.