Fixtures & Tooling

A Variety of Fixtures

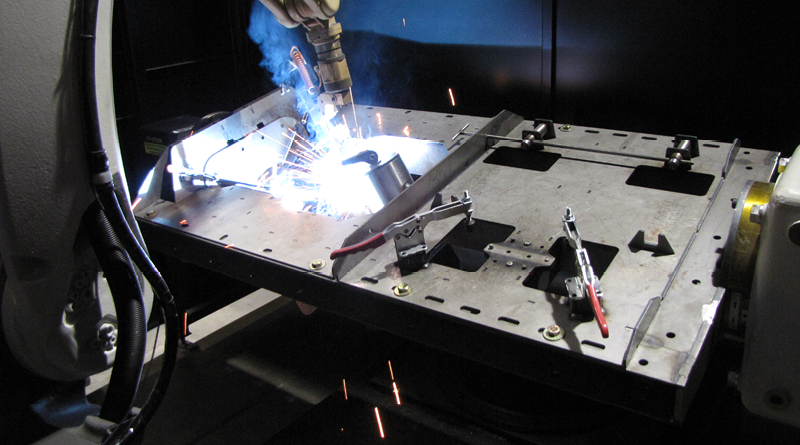

Linde can provide many types of fixtures for your automation needs. Depending on the complexity of the part and the level of interface you require, a tool can be designed to seamlessly integrate into your welding cell. Tooling fixtures usually are made of wear-resistant materials to help ensure long life and part accuracy and can come in a variety of forms including:

- Simple hand clamping fixtures

- Progressive tooling

- Cut through base plates

- Holding and tacking fixtures

- Smart tooling with HMI interfaces

Simple Hand Clamping Fixtures

It is common to manually load and unload parts while needing clamps to hold all the parts in place. The benefit of this simplicity is that hand clamps are relatively inexpensive and can be easily replaced after wear.

Progressive Tooling

Progressive tooling is used when a part’s components cannot all be welded at once due to either a need for repositioning (the robot cell may not have the ability to rotate parts) or sub components needing to be welded separately for a final part to be completely. When designed, there may be several part fixture cavities on the load side of the robot. As a part gets welded in the first fixture cavity and is moved manually to the next fixture cavity and so on, until a completed part is completed in the final fixture cavity. Each rotation of the robot cell table would produce a finished part in the final fixture cavity. This configuration would be mirrored on both sides of the robot.

Cut Through Base Plates

Cut through base plates are commonly used when a tooling plate is on a rotating head stock tail stock. These access holes simply allow the welding torch access to be able to weld the bottom of the part.

Holding and Tacking Fixtures

Some parts to be welded can be very large or heavy. Loading these components into a robot fixture can be cumbersome and can limit torch accessibility for the welding robot. When this occurs, a tacking fixture is often used to hold the part together without falling apart. The tacked but un-welded part can be then placed into a simple holding fixture on the robot cell with minimal clamping to ensure easy torch access to all the welds.

Smart Tooling with HMI Interfaces

Smart tooling is used to give fixtures a level of automation for purposes such as:

- Ensuring all parts are present using proximity sensors

- To quickly change programs through a HMI interface

- To actuate clamps during the welding process

- To have a part auto load or auto eject a part in the cell

All these help ensure quality and productivity of the robot cell.