Stargon™ AL for Aluminum

A Shielding Gas Designed And Optimized For Aluminum GMAW And GTAW Welding Processes

Linde’s Stargon™ AL welding blend is an advanced shielding gas for welding aluminum. Stargon AL welding blend is a carefully prepared proprietary blend of argon with precisely controlled ppm (parts per million) additions of active gases, and it is versatile for use in both GMAW and GTAW weld processes.

When compared to pure argon,

Stargon AL shielding gas provides better arc control, penetration and weld puddle placement, resulting in improved weld speeds and weld quality.

By increasing arc stability, arc energy and overall arc performance, Linde’s

Stargon AL welding blend improves bead appearance, can reduce the cleaning zone, and provides better wetting and weld penetration – increasing process weld quality and operator appeal.

Stargon AL Welding Blend GMAW Performance on Aluminum

Stargon AL welding blend increases arc stability, energy and performance in GMAW processes, which provides better wetting, fusion and penetration, when welding aluminum. It also improves weld quality, bead appearance and operator appeal.

Features

- Bead Appearance - Stargon AL gas blend provides a consistent, regular arc with reduced surface tension for better wetting and a smoother bead with reduced spatter.

- Better Arc Stability – Stargon AL gas blend provides improved weld fusion and penetration when compared to argon.

Stargon AL Welding Blend GTAW Performance When Welding Aluminum

Stargon AL welding blend powerfully impacts the GTAW weld process. The improved arc stability, energy and performance provide significant gains in weld placement and bead appearance, the reduction of the cleaning zone, and improved weld fusion and penetration, as well as faster travel speeds.

Features

- Bead Appearance – Welds made with Stargon AL gas blend result in a smaller cleaning zone with a smoother weld surface.

- Weld Penetration – Stargon AL gas blend provides greater penetration than argon.

- Arc Stability – Stargon AL gas blend provides improved stability and wetting, with less arc wander.

Performance Characteristics

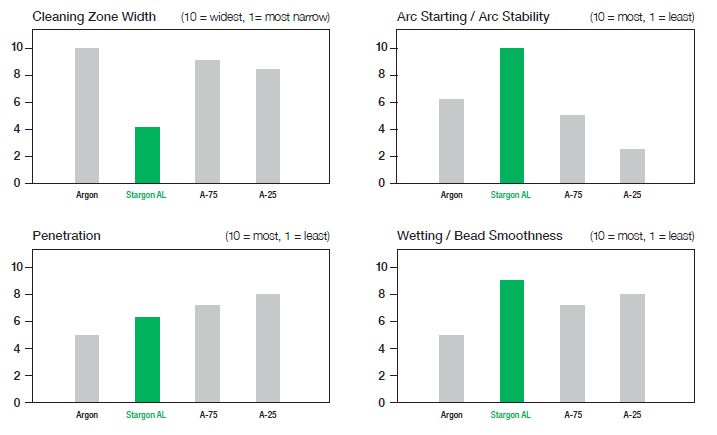

The charts below compare Linde’s Stargon AL welding blend and other shielding gases. To discover the best shielding gas options for your application, contact your local Linde representative.

TIG Welding Suggested Parameters

| Shielding Gas | Aluminum Thickness (inches) | Tungsten Electrode Diameter (inches) | Current Level (amp) | Filler Diameter (inches) | Gas Flow (cfh) |

|---|---|---|---|---|---|

| Stargon AL | 1/16 - 1/8 | 1/16 - 3/32 | 60 - 150 | 3/32 - 1/8 | 15 - 20 |

| 3/16 | 1/8 | 180 - 220 | 1/8 | 20 - 25 | |

| 1/4 | 3/16 | 220 - 300 | 1/8 - 3/16 | 25 - 30 | |

| 3/8 | 3/16 - 1/4 | 280 - 370 | 3/16 | 30 - 35 |

MIG Welding Suggested Parameters

| Shielding Gas | Wire Diameter (inches) | Aluminum Thickness (inches) | Wire Feed Speed (ipm) 4xxx | Wire Feed Speed (ipm) 5xxx | Amps 4xxx | Amps 5xxx | Volts 4xxx | Volts 5xxx |

|---|---|---|---|---|---|---|---|---|

| Stargon AL | 3/64 | 3/32 | 170 | 220 | 110 | 120 | 25 | 24 |

| 1/8 | 270 | 330 | 150 | 160 | 26 | 25 | ||

| 1/4 | 320 | 370 | 190 | 220 | 26 | 25 | ||

| 3/8 | 390 | 450 | 220 | 230 | 27 | 25 | ||

| 1/16 | 1/4 | 170 | 200 | 200 | 210 | 26 | 24 | |

| 3/8 | 200 | 230 | 230 | 240 | 27 | 25 | ||

| 1/2 | 240 | 270 | 260 | 270 | 28 | 26 | ||

| 3/4 | 260 | 300 | 280 | 290 | 29 | 27 | ||

| 1 | 280 | 320 | 300 | 310 | 30 | 28 |