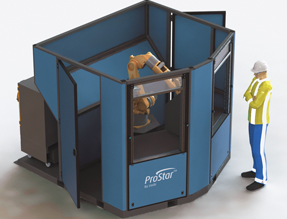

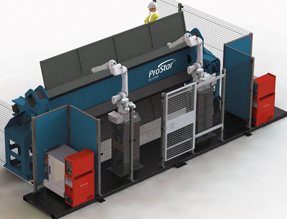

PROSTAR Pre-Engineered Robotic Welding Cells

High Speed Production Welding Systems

Linde Gas & Equipment robotic cells are designed for creating repetitive parts of various shapes and sizes, thanks to their wide range of automation and process choices. These cells support different OEM options, including six-axis robotic arms, controllers, positioners, and consumables from top brands.

Our cells come in different configurations to accommodate various weldment sizes and shapes. They feature flexible loading options, modular tables, Ferris wheel functionality, alternating workstations, multi-axis positioners, and more. Their work cells are spacious and have built-in wiring paths that can handle most controllers, power sources, and accessories. PROSTAR™ work cells offer modular tooling bridles and can be customized to fit larger tables and one-axis or two-axis positioners for complex weld geometries.

Pre-Engineered Robotic Welding Cell Benefits

![]() Engineered for Safety

Engineered for Safety

→ RIA-compliant safety features

→ Operator protection from harmful sparks

and UV radiation

→ Light curtain protective boundary

→ Ergonomic loading height, rear/side maintenance doors (some models)

![]() Freedom of Choice

Freedom of Choice

→ Choose your robot and welding process.

→ Specify single-axis or multi-axis

positioners

→ Choose one, two or three workstations.

→ Specify fixed or modular table configurations.

ProStar Pre-Engineered Welding Cell Types

2 or 3 Doors: 1 AXIS - 2 or 3 modular adjustable tables, telescoping pneumatic doors, single robot.

Angle Loader: 1 AXIS - 2 fixed tables, telescoping pneumatic doors, side-cell access.

Ferris Wheel: 3 AXES - 2 robots / stations, 360° single-axis positioners, 180° servo-driven indexing wall.

Front Loader: 1 AXIS - 2 fixed tables separated by a 180° servo-driven indexing wall.